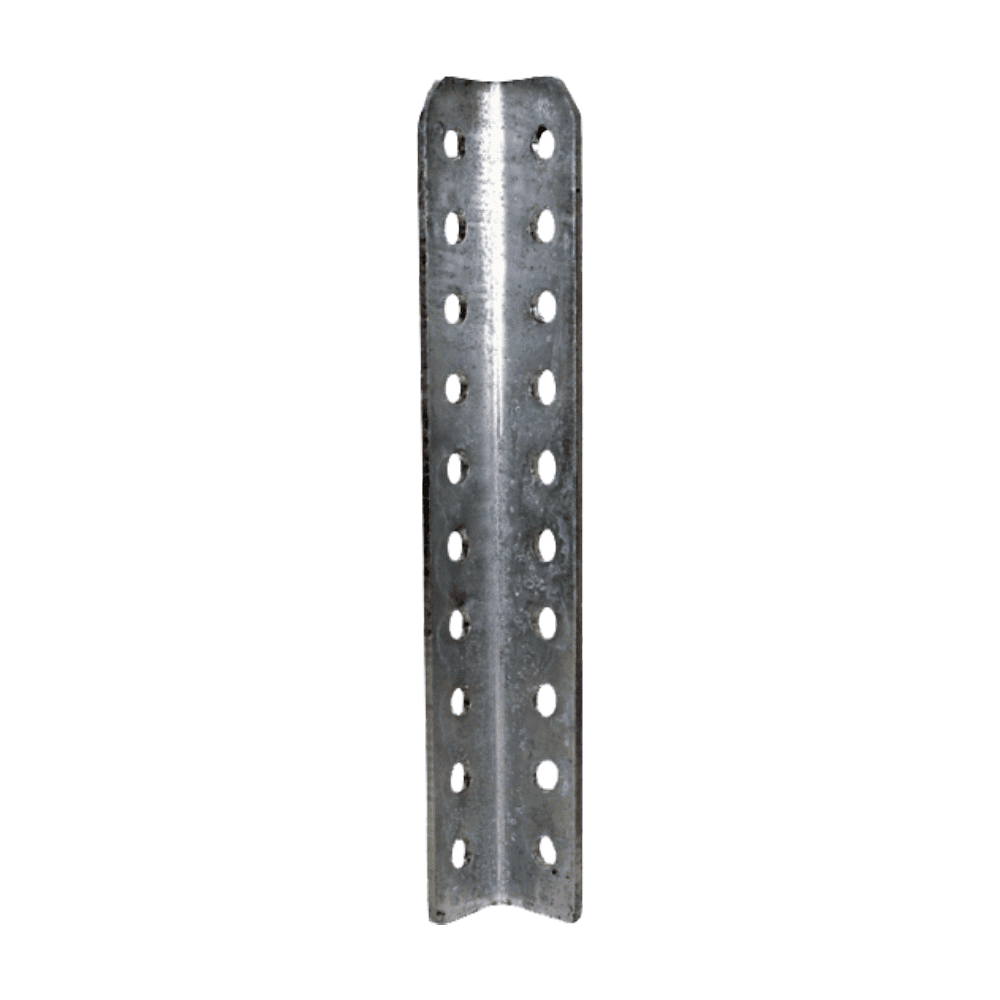

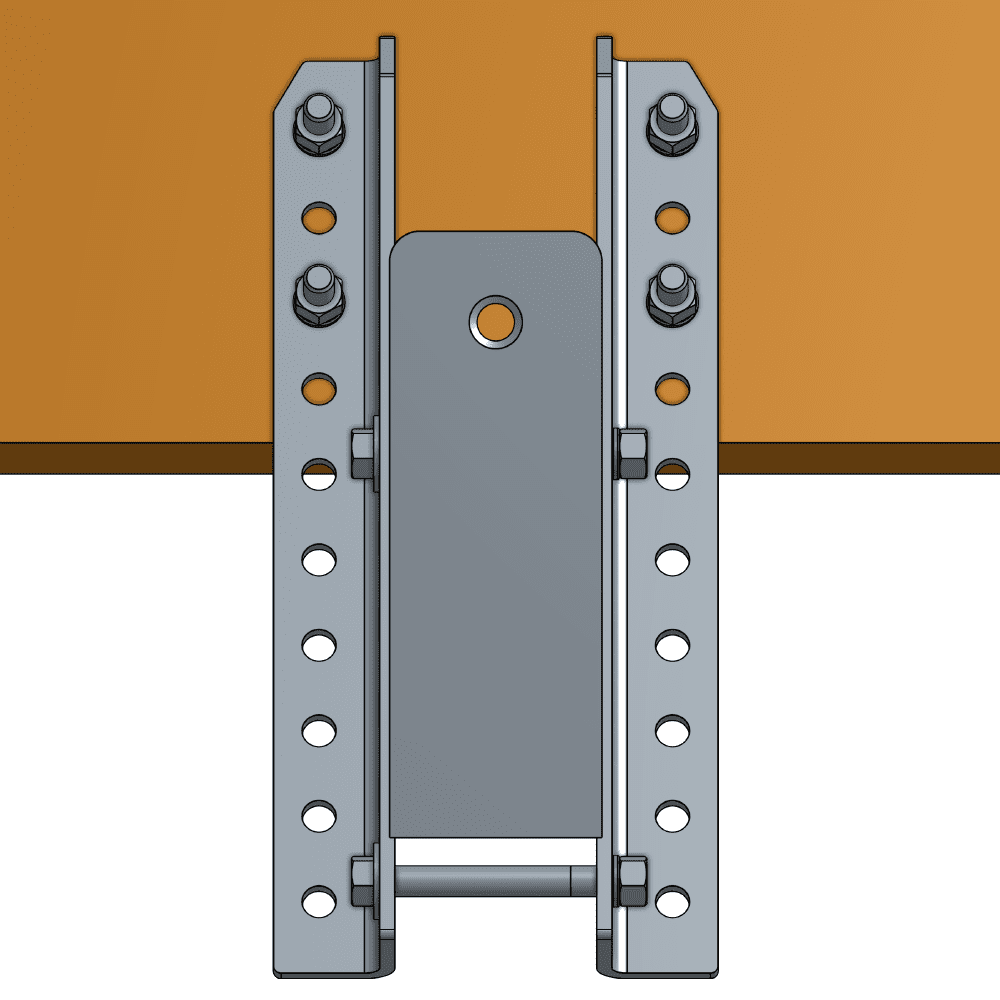

Galvanized Chock Angle Bracket

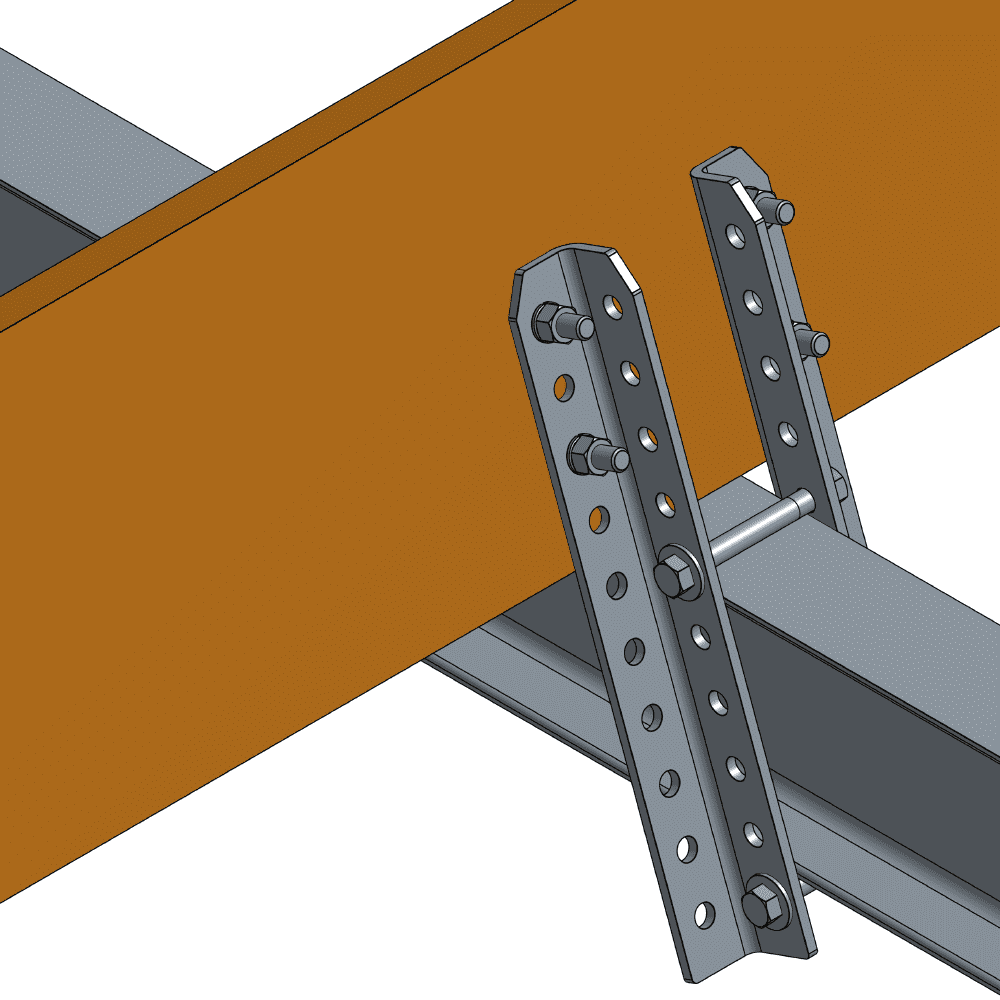

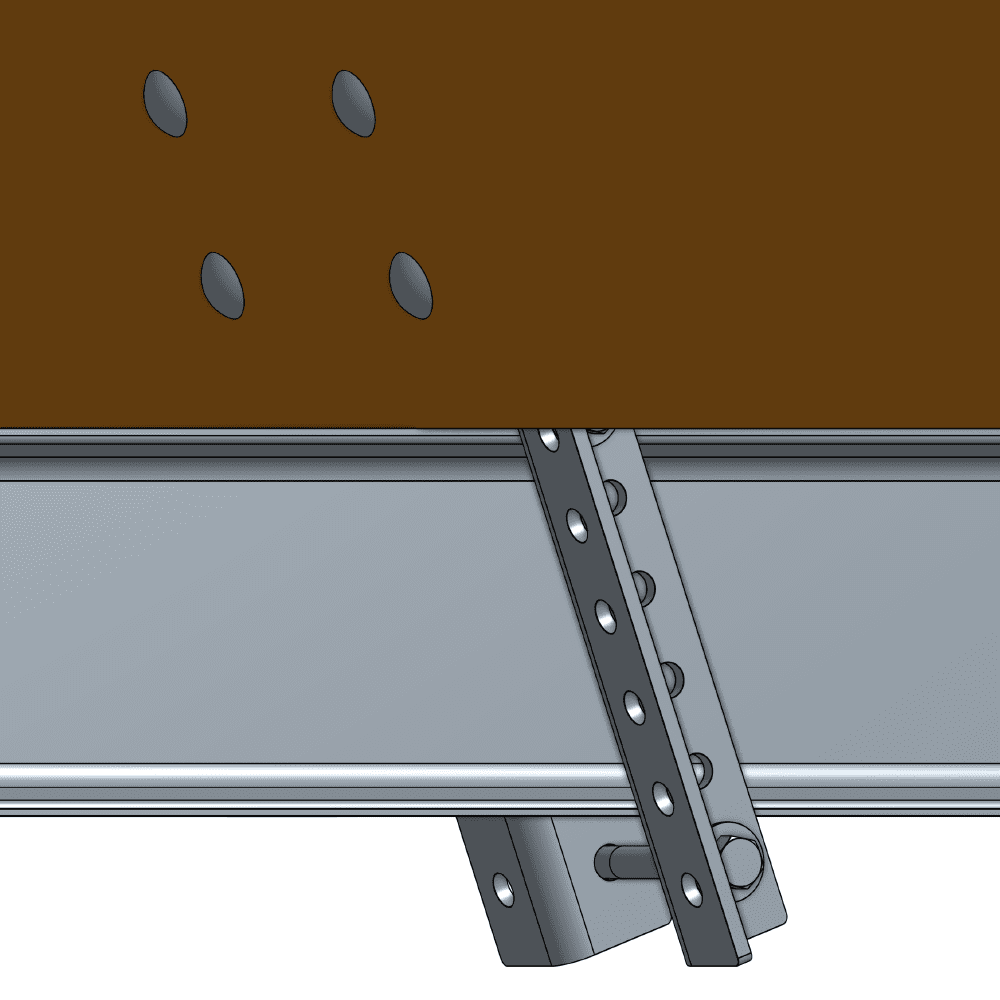

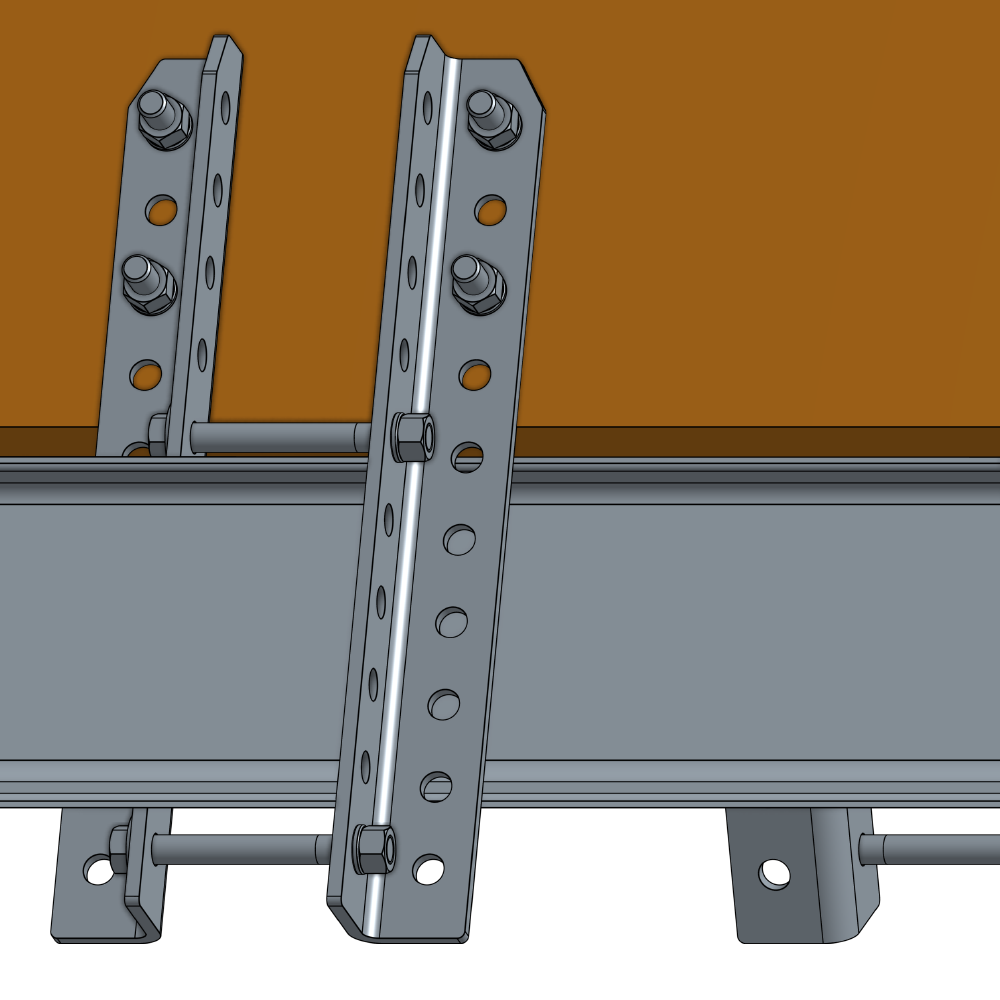

The Galvanized Chock Angle Bracket features 1/4 in. thick laser-cut steel. Used to mount wood bunks to galvanized cradle beams. A universal bracket with a professional look. Made from 1/4 in. hot-dipped galvanized steel. Features 9/16 in. mounting holes on both sides of the flange. Fits bolts up to 1/2 in. Use carriage bolts for wood beams. Direct matches to Ace Lab’s chock angles.

Mounting fasteners are not included.

Specifications

| Size: | 12 in. | 16 in. | 22 in. |

| Cradle Beam Height: | 4 in. | 5 in. | 6 in. |

| Flange Size: | 2 5/8 in. | 3 in. | 3 3/8 in. |

| Ace Labs #: | 834BH | 834 | 834L |

| Weight: | 3.25 lbs. | 3.5 lbs. | 4.5 lbs. |

| Measurements: | 12 in. x 2 in. (each flange) | 16 in. x 2 in. (each flange) | 22 in. x 2 in. (each flange) |

| Mounting Hole Size: | 9/16 in. |

9/16 in. | 9/16 in. |

| Hole Spacing: | 1 1/2 in. (center-to-center) | 1 1/2 in. (center-to-center) | 1 1/2 in. (center-to-center) |

| Material: | Steel | Steel | Steel |

| Finish: | Hot-dipped galvanized | Hot-dipped galvanized | Hot-dipped galvanized |

Product Overview

- Hot-dipped galvanized steel

- Stamped from 1/4 in. steel

- Laser-cut for a professional look

- Direct matches to Ace Labs angles

- Fits many types of I-beam boat cradle styles

- Multiple lengths include 12 in., 16 in., and 22 in. long

- Single angle with no mounting fasteners

Related Products

You may also like...

-

Yellow Weighted Boat Lift Sling

$102.90 – $261.07 Select options -

5 in. Galvanized Cradle Beam

$365.13 – $470.10 Select options -

Galvanized Pontoon V Bunk Bracket Kit

$120.36 – $450.36 Select options -

Galvanized Chock Angle Bracket Kit

$250.17 – $431.30 Select options