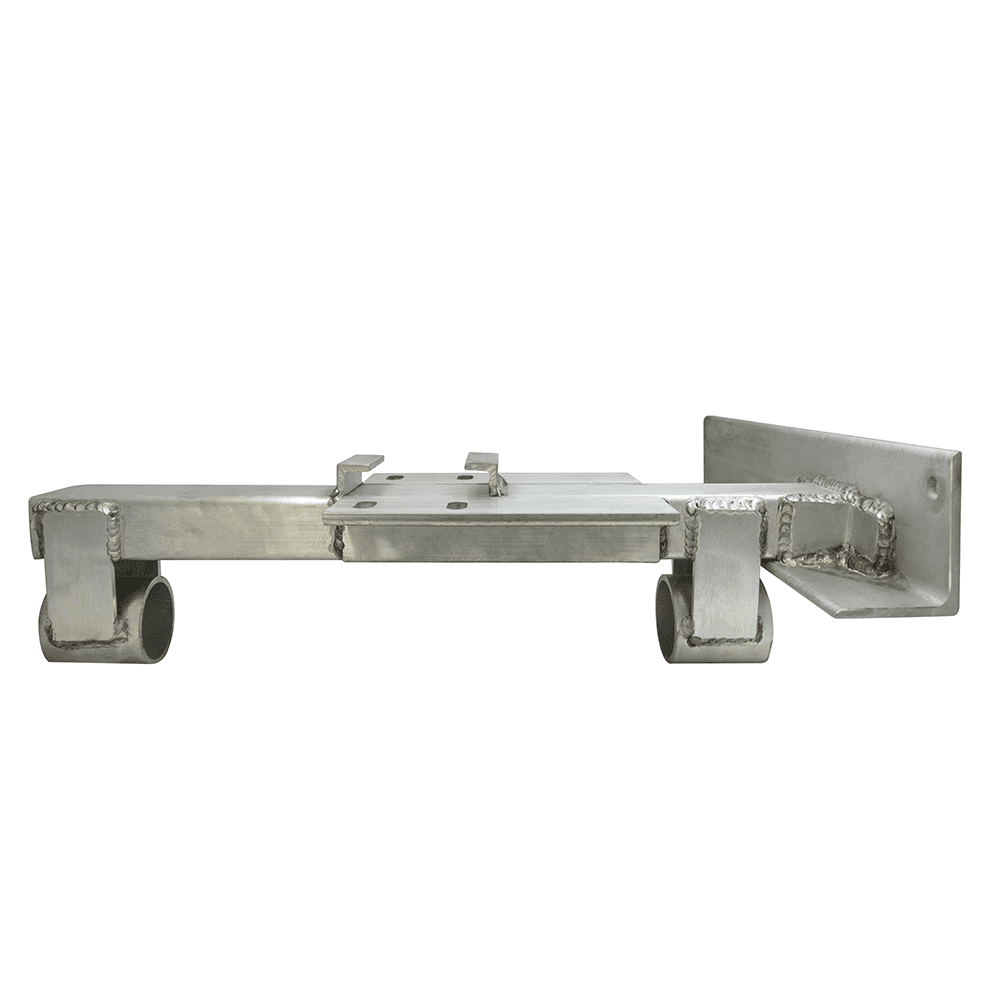

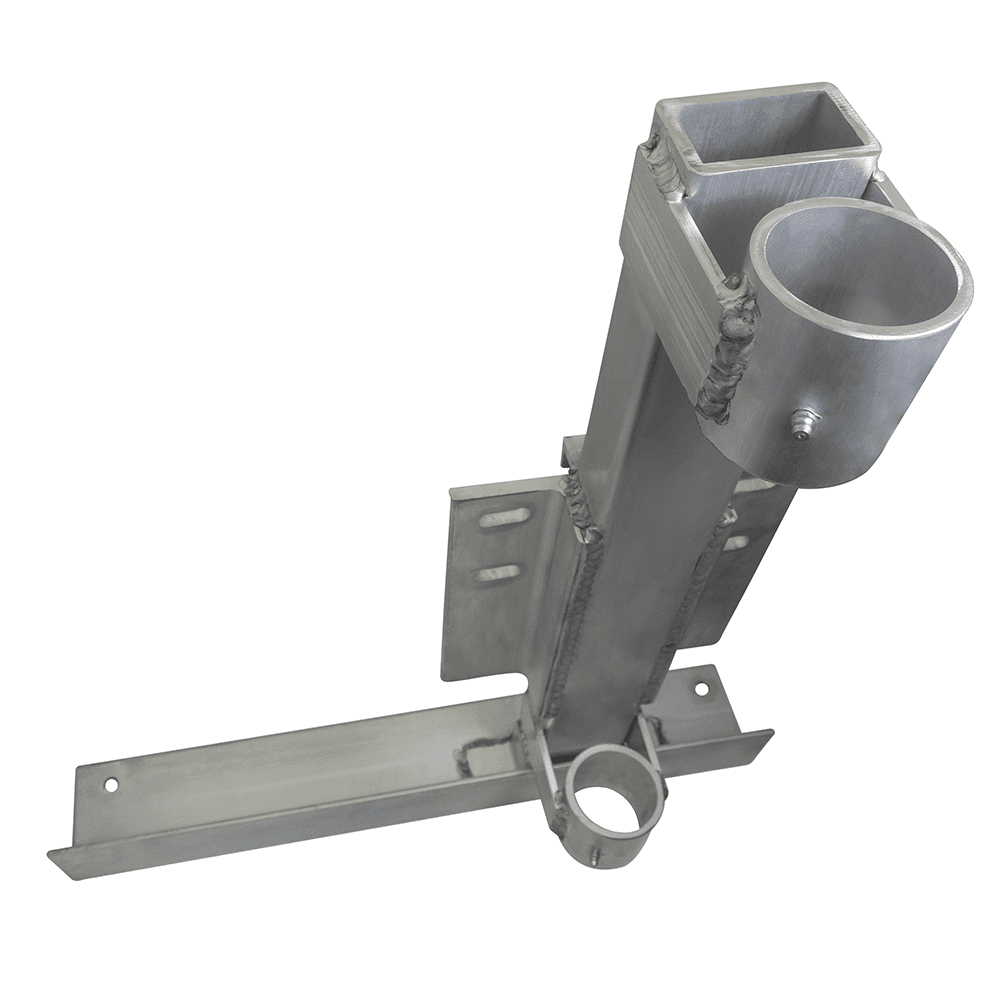

Flat Plate Hoist Hanger for Aluminum Beams

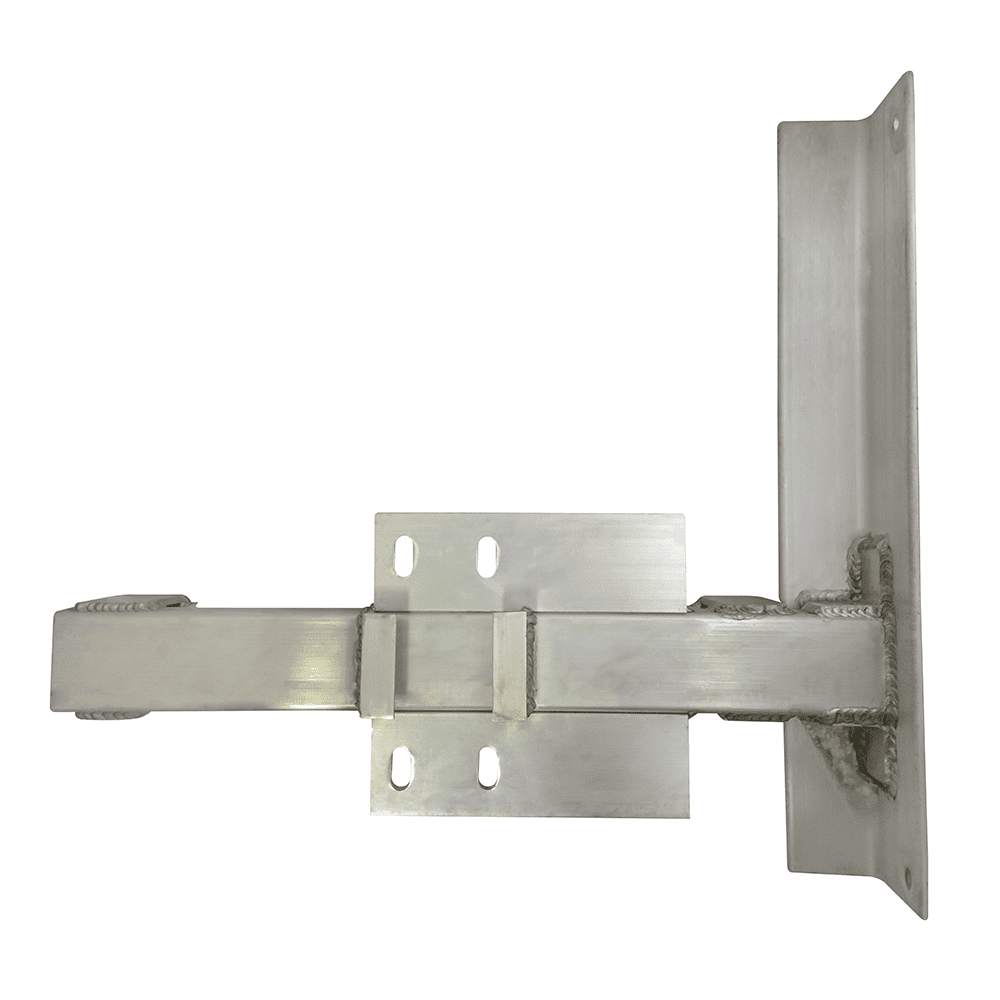

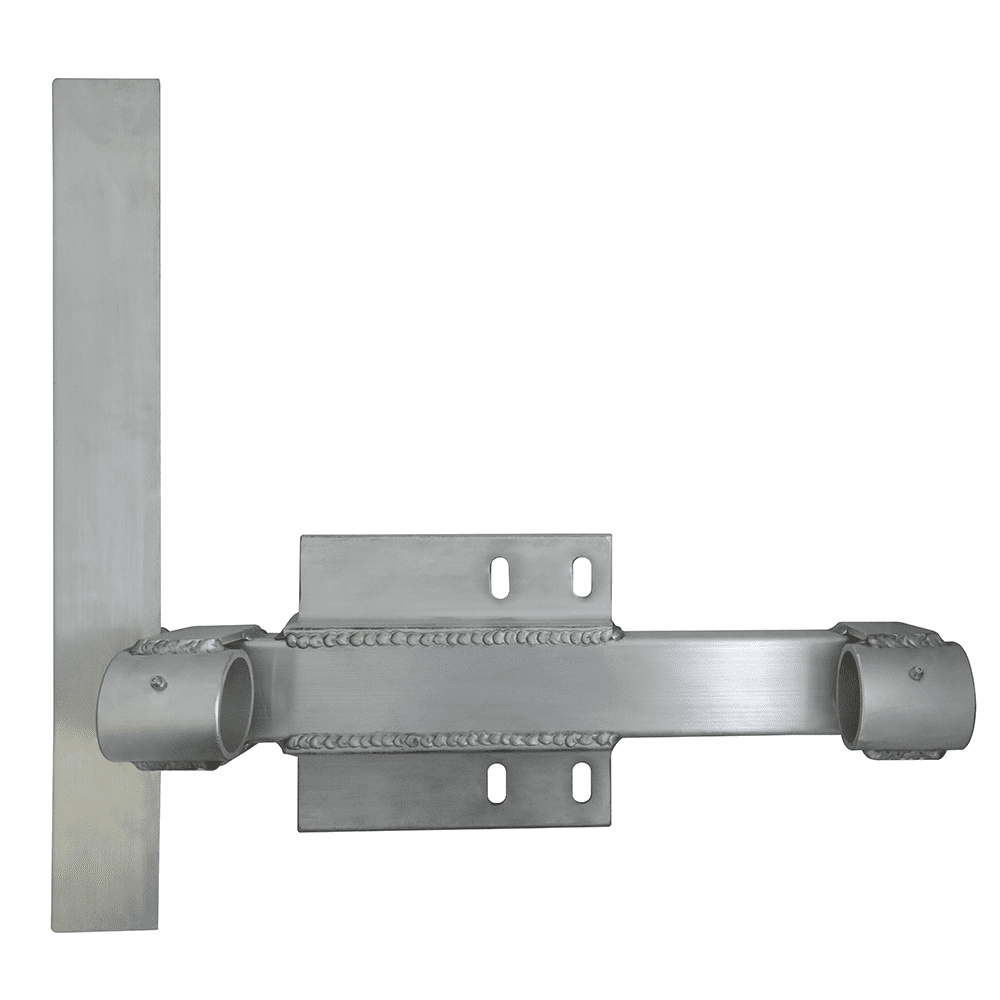

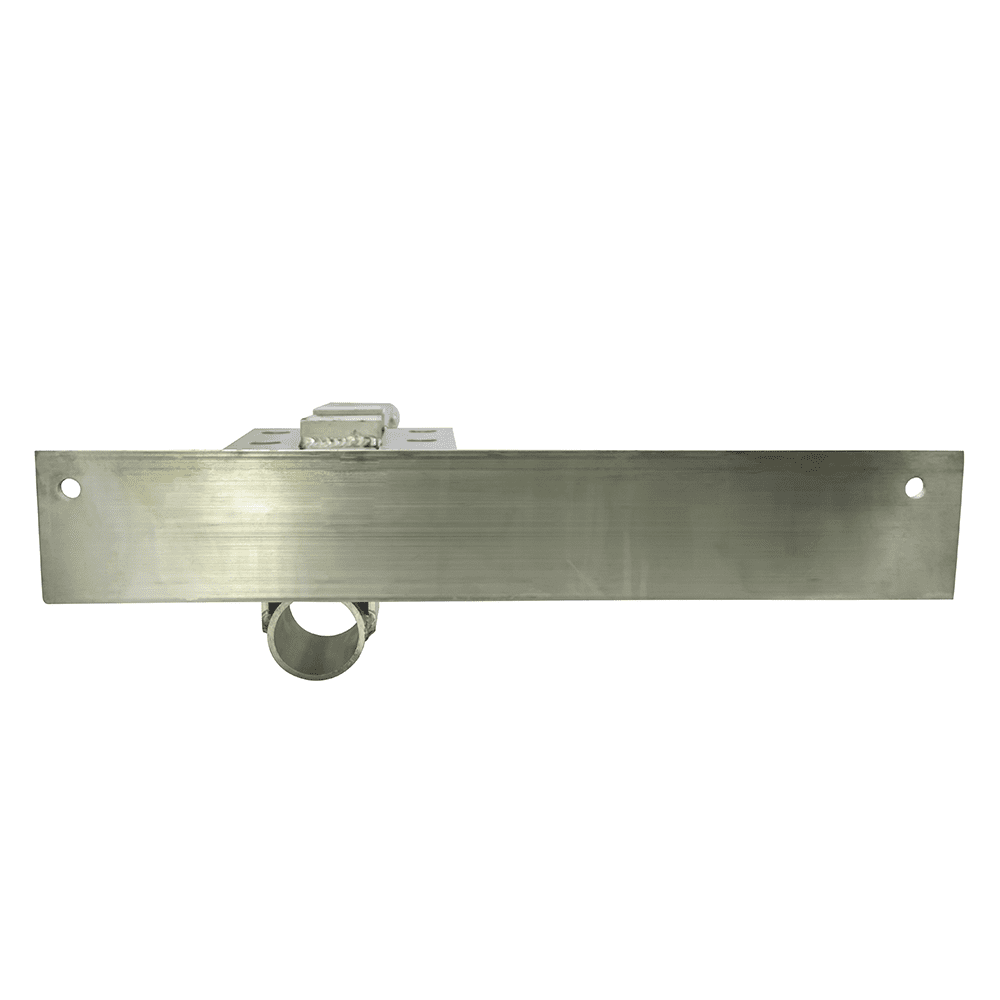

The Flat Plate Hoist Hanger mounts to overhead aluminum structural beams. Slides onto the flange of the beam. Used in center-mounted overhead boat lifts. Includes dual-drive pipe support. Accepts 2 in. ID / 2 3/8 in. drive pipes. Each sleeve has a 1/4 in. grease fitting. Allows for easy greasing of the drive pipe. Includes flat=plate hoist mounting bracket welded to the pipe support. Uses standard flat-plate mounting holes.

Made from 6061-T6 US aluminum. Allows for option cable winder between the sleeves. Mount boat hoist horizontally for maximum overhead clearance. Fits 6 in. Web x 4 in. flange beam. Easy installation on boat lifts.

Dual pipe supports, with or without hoist hanger, is best used in a center mount configuration. A 4,000 lb. maximum rating per hoist hanger when used correctly in center mounting. Side mounting greatly reducts the dual pipe support and hoist hanger capacity. A 1,000 lb. maximum rating when used correctly for side mounting. See the attached guide for more information and limitations.

Drill (4) holes into the hanger flange directly under the i-beam and then mount the boat hoist.

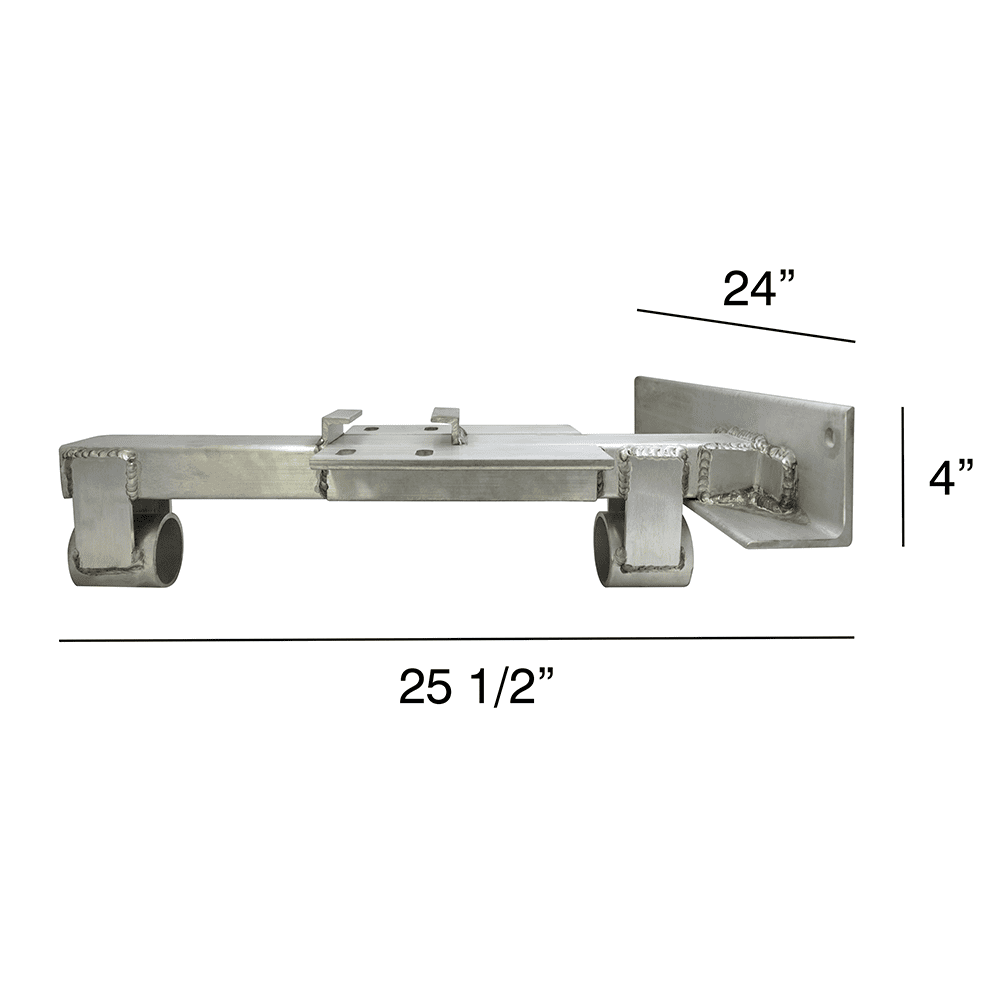

Specifications

| Dimensions: | 25 1/2 in. L x 24 in. W x 4 in. H |

| Weight: | 15.85 lbs. |

| Center Mout Maximum Rating: | 4,000 lbs. |

| Side Mount Maximum Rating: | 1,000 lbs. |

| Material: | Aluminum |

| Type: | 6061-T6 US |

| Drive Pipe Accepts | 2 3/8 in. OD (2 in. ID) |

| Boat Hoist Mount: | Horizontal |

| I-Beam Flange: | 4 in. |

| Grease Fitting Size: | 1/4 in. |

| Grease Fittings: | 1 (per sleeve) |

Center-mount pipe supports are only recommended for center mount or twin mount installations. It is not recommended to use pipe support on a side mount installation. Never attempt to straight-line lift any more than 4000 lbs on a side mount overhead lift or straight line more than 6000 lbs on center or twin mount lifts. Only use the full length of the pipe to connect both pipe supports.

Do not attempt to use two short pieces of the drive pipe. If designing or engineering your overhead lift, you must download and read the BH-USA overhead boat lift guide that can be found on this page. Also available in the tech guide section. BH-USA makes available complete engineered and rated lifts and highly encourages choosing this option over designing and engineering a boat lift on your own.

The above ratings of the dual pipe supports are only valid if installing or using the pipe supports with the BH-USA overhead boat lift guide. The Side Mount and Twin Mount ratings are based on straight line pull. Rating is based on per pipe support and not per boat lift. When considering the weight of your boat, you must use full wet weight plus the weight of the boat cradle. (wet weight + boat cradle weight = total lifting weight)

BH-USA engineers and manufactures factory-rated complete boat lifts. We highly recommend purchasing one of these boat lifts instead of building your own. If you, or your installer, buys parts and pieces to engineer your custom boat lift, it will no longer be considered a Boat Hoist USA engineered boat lift.

Product Overview

- Designed for center mounting

- Fits 4 in. aluminum beams

- 6061-T6 marine-grade US aluminum

- Dual pipe supports come with installed 1/4 in. grease fittings

Related Products

You may also like...

-

1 HP Heavy Duty Elite TENV Bremas Wired Motor with Base

$570.62 – $691.37 Select options -

6,500 lb. Deluxe Gear Plate Assembly

$546.95 – $599.63 Select options -

Flat-Plate Hoist Front Cover

$77.96 – $84.99 Select options -

Flat-Plate Hoist Back Cover

$42.67 – $47.00 Select options